LVE-12M Video-Extensometer

LVE series video extensimeter is a non-contact high-precision real-time measurement system, it uses a separate digital camera and real-time image processing algorithm.

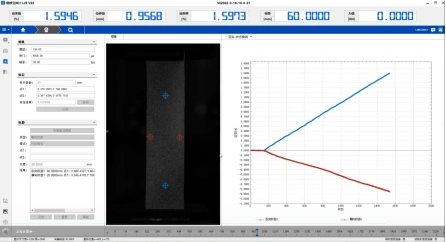

By shooting the image of the test specimen experiment process and analyzing the characteristics changes of the image,it can dynamically measure the real-time strain, displacement and other data.

It can transmit signals with the testing machine to measure the stress-strain curve and other mechanical properties parameters. This device is suitable for all kinds of mechanical tests.

Characteristic

Non-contact measurement :Avoid the additional influence of contact means such as strain gauge and grip extensometer on measurement.

Whole process tracking: the whole process does not need to stop, the sample fracture will not damage the measuring device, the whole process is being tracked.

Multiple application scenarios:In addition to general scenarios, it can also adapt to large deformation, small deformation, high and low temperature and other special experiments.

Wide range of application:The material is basically unlimited, and the test can be carried out for samples with different sizes and different materials.

Sub-pixel level measurement accuracy: Based on the image processing algorithm, the calculation accuracy reaches sub-pixel level.

Large strain range:Equipment can measure strain ranges from 0.002% to more than 1000%, far exceeding traditional methods.

Customer scale:Customize the scale size which can be set within hundreds of millimeters.

Multidirectional simultaneous measurement:The longitudinal and transverse strains can be calculated simultaneously.

Multi-pointpair simultaneous measurement :Equipment can measure the strain in multiple point pairs and is suitable for multi-sample test and multi-section test.

Instruction of software function

Acquisition function

Camera compatibility

Support USB3.0 camera interface;

Automatically obtain camera parameters,plug and play,easy and fast.

Free frame

Cut the frame by free frame selection mode with mouse,quickly set the measurement target area and improve the measurement speed;

Real-time display of clipped frame size and frame rate;

Auxiliary line correction alignment function;

System calibration

Support two modes:automatically calibration and custom calibration;

With automatic calibration function.

Gauge setting

Three gauge modes:free scal,industry scale,fine wire gauge

In real-time measurement mode,support set 10 groups gauge simultaneously;

Support horizontal and vertical gauge setting.

Acquisition mode

Support interval acquisition;

Support fatigue and unmonitored creep deformation test.

Image storage

Support interval storage,memory storage and trigger storage;

Storage can be closed at any time.

Communication function

Support real-time digital and analog signals communication input and output;

Support simultaneous control with test machine date;

2 output ports, 16 input ports;

16 bit data accuracy.

Blue light photosource

LED blue light technology, no stroboscopic, uniform lighting field;

Electrodeless light source brightness adjustment;

Slide rail device

Manual slide rail,support upgrade electric slide rail;

Free adjustment of measuring distance and range.

Analysis function

The calculate mode

Three modes: real-time,calculation and collection;

Real-time calculation of gauge, point data and curve, real-time output;

Supports tracing original gauge data and redefining gauge analysis,

Support external image import calculation.

Multithreading computing

Multi-thread calculation, effectively improve the real-time calculation speed.

Displacement measurement

Support point, point pair and gauge displacement and deformation measurement.

Strain measurement

Support longitudinal and transverse real-time strain measurement;

comes with maximum elongation rate measurement.

alculation of material properties

Elastic Modulus;

Poisson’s ratio.

Zero setting function

Measurement original point quick make zero function,start a new measurement project at any time.

Data Storage

Real-time data output, support Excel format;

Support all data export, select data export, mantissa export;

Curve analysis

real-time multi-curve rendering;

Supports curve data deletion;

Support curve hiding;

Support curve enlargement, diminution, translation, reset;

Data display

Intelligent suspension mode

Convenient multi-software interactive operation,multi-window collaborative display ;

Start,stop,switch display value control;

Curve mode

Curve drawing function: displacement – time series curve, strain – time series curve, force – time series curve, stress – strain curve;

Status bar display

Display picture size and collect frame rate and other information in real time.

Screenshot

With screenshot function.

Real-time coordinates

Display the position and coordinate of the current gauge points in real time;

Time sequence axis management

Time sequence axis manage data status;

View different time status data, images, and curves simultaneously.

Noise Shield

With dual image and data noise shield function, can eliminate the effect of small high-frequency vibration;

The noise shield level can be set to low, medium, and high by default or can be customized.

Type and parameter table

| Type | LVE-12M |

| Distinguishability | up to 0.5μm |

| Displacement accuracy | up to ±1μm |

| Test vision | standard:60mm-150mm adjustable

extend:150mm-1000mm adjustable |

| Available gauge range | standard:<100mm

extend:<1000mm |

| Real-time acquisition rate | Maximum 200fps |

| Extensometer accuracy grade | ISO9513 grade :0.5 (standard) |

Standard hardware configuration table

| Type | LVE-12M |

| Software | LVE2023 PRO version software installation package and coded lock |

| Measuring head | 12M Standard integrated measuring head

Including camera,lens,shell,light source and slide rail |

| Control box | 16-bit precision analog input and output; Brightness adjustment knob |

| Support | tripod+Pan-Tilt |

| Staff | RU-60、RU-20 |

Equipment software

The computer and operating desk should be provided by customers, and the standard configuration does not include the computer and operating desk.