DF81.400 series HDT & VICAT testing system

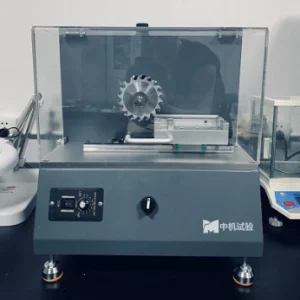

Name: Microcomputer controlled thermal deformation Vicat softening point testing machine (model: DF81.400)

- Standards

- GB/T 8802-2001 “Determination of Vicat softening temperature of thermoplastic pipes and fittings”

- GB/T 1633-2000 “Determination of Vicat softening temperature (VST) of thermoplastic materials”

- GB/T 1634.1-2019 “Determination of plastic deformation temperature under load – Part 1: General test method”

- GB/T 1634.2-2019 “Determination of Load Deformation Temperature of Plastics Part 2: Plastics, Hard Rubber and Long Fiber Reinforced Composite Materials”

- ASTM D648-01 “Standard Test Method for Deformation Temperature of Plastics Under Flexural Load in the Edgewise Position”

- ISO75-1-2013 Determination of plastic load deformation temperature

- Main technical parameters

- Temperature control range: Room temperature to 300 ℃

- Temperature accuracy:±0.5℃

- Uniform heating rate: A speed: 5 ± 0.5 ℃/6min; B speed: 12 ± 1.0 ℃/6 minutes

- Medium: Silicone oil or transformer oil, approximately 25L (to be provided by the user)

- Deformation measurement range:>10mm

- Deformation resolution: 0.001mm

- Deformation measurement accuracy: 0.005mm

- Loading:

- Vicatload:GA=10N±0.2N, GB=50N±1N

- Maximum bending normal stress during thermal deformation:

Method A, using fiber stress of 1.80MPa

Method B, using fiber stress of 0.45MPa

Method C, using fiber stress of 8.00MPa

- Cooling method: Chiller circulation cooling (silicone oil within 200 degrees, cooling time ≤ 50min)

- Equipped with upper limit temperature protection function setting

- Number of test racks: 4

- Host power supply: AC three-phase five wire 380V ± 10% 50Hz 5kW

- Overall dimensions of the host (length x width x height): approximately 645mm x 670mm x 1450mm

Host weight: approximately 200kg

- Standard configuration

No. Item Qty Unit Marks 1 Machine host DF81.400 1 pc 2 Test racks 4 set 3 Thermal deformation Indenter 4 pc 4 Vicat Indenter 4 pc 5 Dial gauge 4 set 6 Temperature acquisition module 2 set Main temperature/ Branch temperature of oil tank 7 Temperature sensor 5 pc 8 Weight 1 set 1000g/500g/1g/100g/50g/10g/5g/10N 4 for each pc 200g/20g/2g 8 for each pc 9 LENOVO PC 1 set I3-10100/8G/1T/WIN10 /19.5” 10 Software 1 set 11 Allen wrench 1 set 12 Thermal oil (to be provided by the user) 25 L - Configuration with refrigerator

No. Item Qty Units Marks 1 Machine host 1 pc 2 Test racks 4 pc 3 Deformation sensor 4 pc 4 Temp-control thermal system 1 set RKC 5 Temperature sensor 5 pc 6 Temperature acquisition system 1 set 7 Thermal deformation & Vicat measuring Indenter 4 for each set 8 Weights 1 set 9 LENOVO PC 1 set 10 Printer, Color ink jet 1 pc 11 Software 1 set 12 25L of thermal conductive methyl silicone oil (to be provided by the customer) 1 set 13 Refrigerator, Model: ZLS-5P 1 set - Refrigerator(Model: ZLS-5P) Intro

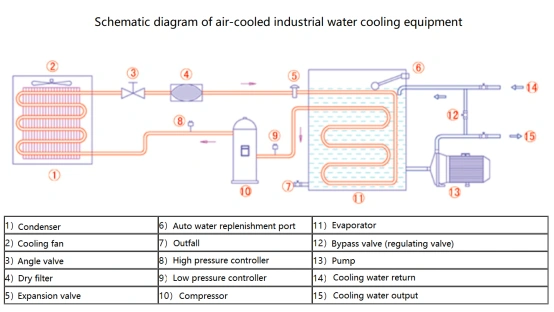

2.5.1 Function

Specializing in high-temperature cooling of laboratory equipment (such as high-temperature furnaces, thermal deformation Vicat, etc.) and UV printing equipment. Promote rapid cooling of the equipment itself or its connecting components, improve work efficiency, and protect the main equipment.

2.5.2 Features

Intelligent control, automatic circulation, automatic cooling, rapid cooling, automatic water replenishment, environmental protection and energy saving, one-time water storage can be used multiple times without waste.

2.5.3 Protection function

Overload protection, Overcurrent protection, Overheating protection, Low temperature protection, High voltage protection, Power reverse/phase loss protection

2.5.4 Technical parameters

- Cooling capacity: 5PS

- Water tank capacity: 55L

- Total power: 4.5KW

- Power supply: 380V, 50HZ

- Medium: Clear water

- Weight: 160KG

2.5.5 Configuration of ZLS-5P

1 set of intelligent control system;

1 set of refrigeration device;

1 set of automatic water replenishment device;

1 set of connecting pipe fittings