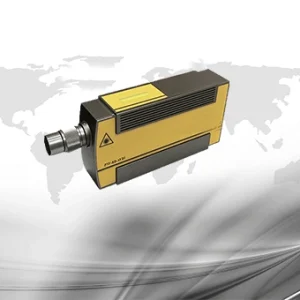

3D Video Extensometer

A non-contact extensometer based on monocular 3D DIC technology. The extensometer measuring head can realize image acquisition during the sample loading process. The extensometer software completes the image calculation and outputs the measured deformation results in real time. After selecting the full-field measurement module, full-field displacement and strain measurement can be realized.

Product advantages

1 It can obtain the force data of the testing machine and generate stress-strain curves;

2 It can automatically identify marking points such as circles, horizontal lines, crosses, and QR codes;

3 It can set the distance between marking points by manually entering the gauge length;

4 It can perform featureless measurement of rebar materials;

5 It meets the existing JJG762-2007 0.5 level accuracy requirements;

6 It is not limited by temperature and can measure under high and low temperature conditions. The measurable temperature range is -190℃ to 2300℃;

7 It is not limited by the strain range and can measure the strain range: 0-1000%;

8 It is not limited by the strain direction: it can simultaneously realize axial and transverse multi-gauge length measurement;

9 It is equipped with a fatigue frequency reduction measurement module, which can collect cross-cycle deformation data by fitting the fatigue loading curve according to the simulated signal of the fatigue testing machine.