1.Overview

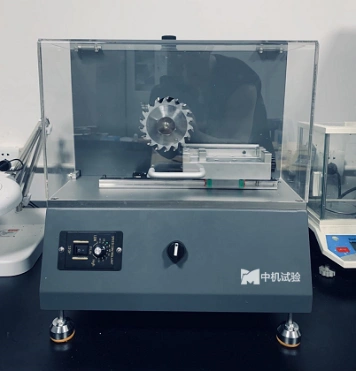

This machine is a specialized cutting equipment for notch specimens used in non-metallic material impact toughness testing using cantilever beam and simply supported beam pendulum impact testing machines.

The equipment is easy to operate and convenient to use, and can process 20 specimens at once.

It uses tungsten steel cutting heads, durable cutting tools, and produces samples with smooth edges and no burrs.

This equipment is suitable for the use of laboratory made notch specimens by users such as scientific research institutions, colleges and universities, and non-metallic material factories.

2.Standards

1.GB/T 1043-2008 “Impact test method for rigid plastic simply supported beams”: Type A and B specimens

2.GB/T 1843-1996 “Impact Test Method for Plastic Cantilever Beams”

3.ISO 179:2000 “Plastics-Determination of Charpy impact properties”

4.ISO 180:2000 “Plastics-Determination of Izod impact strength”

5.ASTM D 256-06 “Standard Test Methods for Determining the Izod Pendulum Impact Resistance of plastics”

3.Main technical parameters

1.Sample types: Type 1, Type 2, Type 3, Type 4

2.Notch type: A

3.Cutting tool parameters: A-type ,45 º ± 30 ¹ r=0.25mm

4.Maximum thickness of sample: 25mm

5.Cutting tool motor speed: maximum 1440r/min (adjustable speed)

6.Host dimensions (L * W * H): approximately 316mm × 366mm × 450mm

7.Host power supply: AC single-phase 220V ± 10% 50Hz 0.5kW

8.Host weight: approximately 30kg

4.Standard configuration

1.Machine host: 1pc

2.1pc of A-type cutting tool (capable of producing V-notches that meet standards GB/T 1043, GB/T 1843, ISO 179, ISO 180, ASTM D 256)