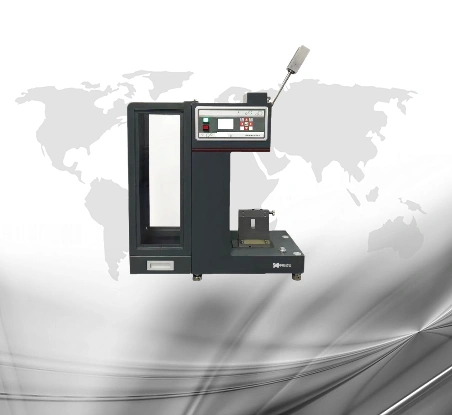

This impact testing machine is designed for the accurate and reliable evaluation of the impact resistance of non-metallic materials, including plastics, nylon, rubber, fiberglass, composite plastic pipes, and electrical insulation materials under dynamic loading. The machine employs a semi-automatic control system that is easy to operate, delivers high work efficiency, and automatically records test data. This instrument is ideally suited for laboratories and manufacturers conducting continuous, high-volume impact testing and provides comprehensive data and reporting capabilities. It is an essential tool for manufacturers, quality control departments, research institutions, and other organizations involved in the development and production of hard plastics.

Key Features:

-

Versatile Material Testing: Suitable for evaluating the impact resistance of a wide array of non-metallic materials.

-

Semi-Automatic Operation: Provides a balance of automation and user control for efficient and straightforward operation.

-

High Efficiency: Designed for high-throughput testing, making it ideal for continuous and extensive testing needs.

-

Automatic Data Acquisition: Automatically captures and stores test data immediately after impact, minimizing error and improving consistency.

-

Dedicated Control Panel and Display: Provides a user-friendly interface for clear display of impact absorption energy, impact strength, pendulum movement angle, and other critical test parameters.

-

Integrated Test Reporting: Enables easy generation and printing of detailed test reports for record-keeping and analysis.

-

Comprehensive Testing Capabilities: Supports both simply supported beam (Charpy) and cantilever beam (Izod) impact tests, catering to various testing standards and requirements.

Main Technical Parameters:

1. Maximum Impact Energy (Simply Supported Beam):

-

50 J

-

25 J

-

15 J

-

5 J

-

4 J

-

2 J

-

1 J

2. Pendulum Moment (Simply Supported Beam):

-

7949 N·m

-

13.3975 N·m

-

8.0385 N·m

-

4.0192 N·m

-

2.1436 N·m

-

1.0718 N·m

-

0.5359 N·m

3. Pendulum Pre-Swing Angle: 150º

4. Angle Resolution: 1º

5. Technical Parameters – Simply Supported Beam (Charpy):

-

Impact Speed:

-

9 m/s (≤ 5 J)

-

3.8 m/s (> 5 J)

-

-

Distance from Pendulum Axis to Specimen Center:

-

230 mm (≤ 5 J)

-

395 mm (> 5 J)

-

-

Impact Blade Angle: 30º

-

Impact Blade Rounding Radius: 2 mm

-

Support Rounding Radius: 1 mm

-

Support Front Angle: 5º

-

Support Rear Angle: 10º

-

Support Span: 40 mm / 60 mm / 70 mm

-

Specimen Sizes (Length x Width x Thickness):

-

80 mm x 10 mm x 4 mm

-

50 mm x 6 mm x 4 mm

-

120 mm x 15 mm x 10 mm

-

6. Technical Parameters – Cantilever Beam (Izod):

-

Impact Speed: 5 m/s

-

Distance from Pendulum Axis to Specimen Center: 335 mm

-

Impact Blade Angle: 75°

-

Impact Blade Rounding Radius: 8 mm

-

Support Front Angle: 5°

-

Support Rear Angle: 10°

-

Distance Between Blade Center and Upper Surface of Jaw: 22 ± 0.2 mm

-

Specimen Sizes (Length x Width x Thickness):

-

80 mm x 10 mm x 4 mm

-

63.5 mm x 12.7 mm x 12.7 mm

-

63.5 mm x 12.7 mm x 6.4 mm

-

63.5 mm x 12.7 mm x 3.2 mm

-

7. Physical Specifications:

-

Overall Dimensions (L x W x H): 740 mm x 260 mm x 870 mm

-

Host Weight: Approximately 10 kg

8. Power Supply:

-

Host Power Supply: AC, Single Phase, 220 V, 50 Hz, 0.5 kW

Key Benefits Highlighted:

-

High Versatility: Supports both Charpy and Izod impact tests.

-

Wide Energy Range: Provides a broad range of impact energy settings to accommodate various materials.

-

Precise Measurements: Designed for accurate and reliable data capture.

-

Efficient Operation: Semi-automatic control and high-throughput capabilities enhance testing efficiency.

-

User-Friendly Interface: Intuitive controls and a clear display simplify operation.

-

Comprehensive Reporting: Facilitates data analysis and record-keeping.